Materials.

We cover the entire materials process

Our expertise

from study to qualification, including simulation and quality control, to precisely meet your needs. We also assist you in the creation of test bench, handling both design and implementation to ensure effective and customized solutions.

Processes.

- Deposition methodologies (metallic coatings, oxidation/corrosion issues).

- Surface treatment of metallic and composite materials in compliance with REACH specifications and standards.

- Light-matter interaction (laser parameters, surface property modification, nanostructuring).

- Simulation

- Simulation of mechanical and vibratory behavior.

- Test-to-simulation correlation and adjustment.

- Finite Element Modeling (GFEM, DFEM).

Control.

- Comprehensive vibratory characterization of composite materials (elastic modulus, loss modulus, density, Tg, tan delta).

- Monitoring of mechanical and thermomechanical characterization tests: fatigue, tension, bending, (micro)hardness, torsion, shearing.

- Recommendations for inspection methods.

- Non-destructive testing and controls (Eddy currents, ultrasound, acoustic emission).

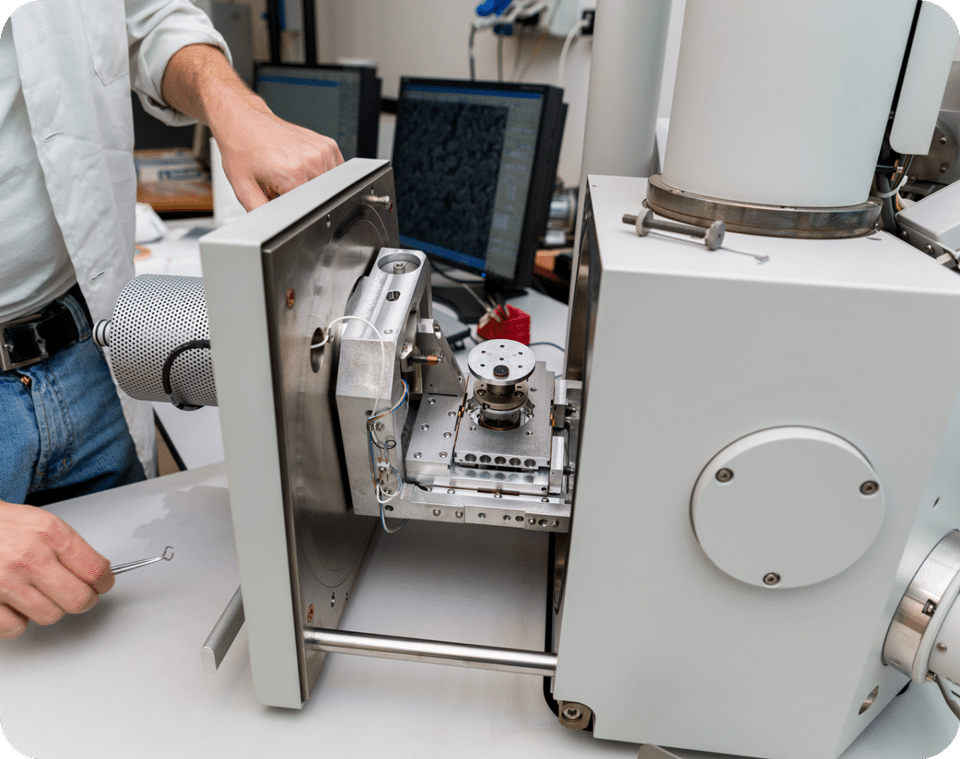

- Imaging (optical microscopy, SEM-FIB, TEM, X-ray tomography).

Qualification.

- Preparation and monitoring of qualification tests for new materials and associated surface treatments: test program definition, supervision of specimen manufacturing, planning and monitoring of tests (mechanical, climatic, electrical, fatigue, salt spray…).

- Drafting of qualification reports.

- Justification and certification for fatigue and damage tolerance.

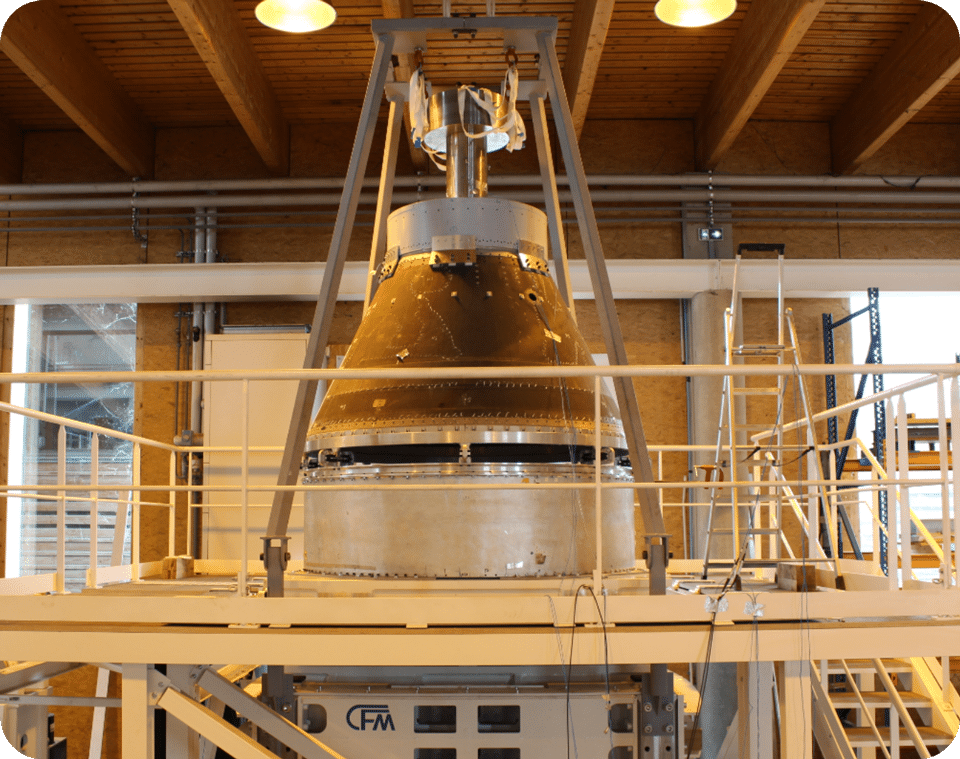

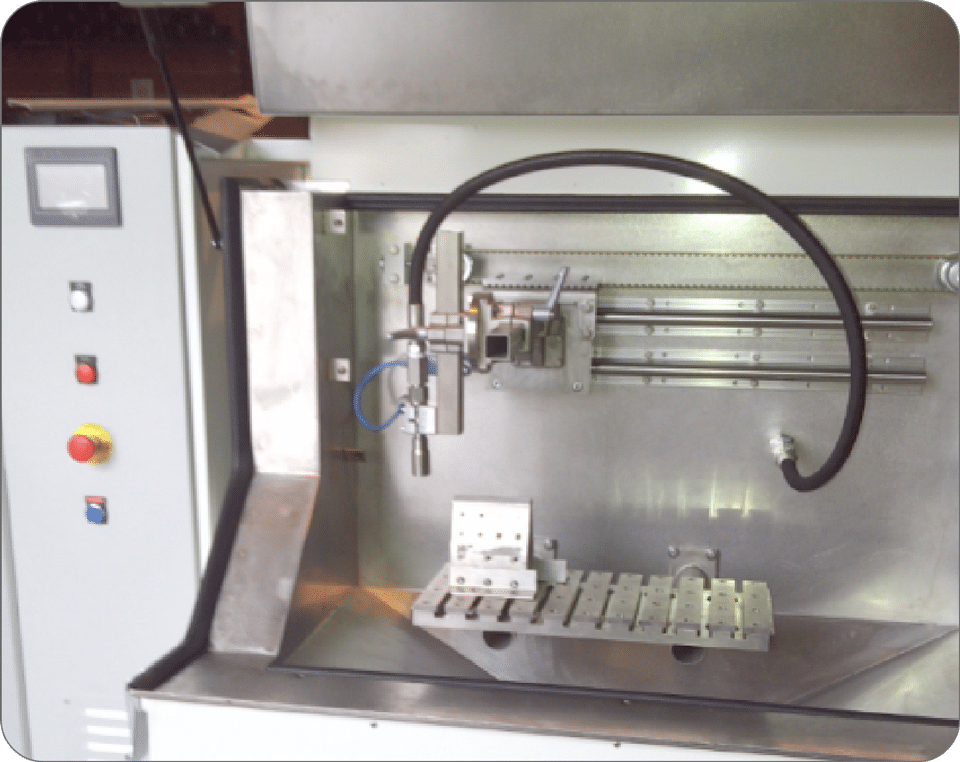

Test Benches.

- Damping measurements of composite materials using specific test benches.

- Design and implementation of material test benches: erosion bench, bending bench for weld characterization, drop bench for composite materials.

They trust us.

Ils parlent de nous.

« Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam ipsum sapien, tempor ac malesuada non, viverra in urna. Nullam mollis orci id tortor fringilla accumsan porta at ipsum. Praesent dui orci, malesuada id nibh vel, eleifend aliquet metus. Proin posuere pulvinar felis at sollicitudin. Nullam et faucibus mauris, eu consectetur nulla. »

AVNIR Group Client

« Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam ipsum sapien, tempor ac malesuada non, viverra in urna. Nullam mollis orci id tortor fringilla accumsan porta at ipsum. Praesent dui orci, malesuada id nibh vel, eleifend aliquet metus. Proin posuere pulvinar felis at sollicitudin. Nullam et faucibus mauris, eu consectetur nulla. »

Laurent M. – AVNIR Group engineer

« Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam ipsum sapien, tempor ac malesuada non, viverra in urna. »

FD. – AVNIR Group Engineer

« Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam ipsum sapien, tempor ac malesuada non, viverra in urna. »

Guilhem M. – AVNIR Group Engineer

« Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam ipsum sapien, tempor ac malesuada non, viverra in urna. »

Florian M. – AVNIR Group Engineer

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Dassault Aviation